JYWQ series automatic mixing sewage pump

Basic Info

Model No.: BODA-107

Product Description

JYWQ automatic mixing sewage pump overview

JYWQ, JBWQ, JPWO series automatic mixing sewage pump is based on the ordinary sewage pump. The automatic stirring device is used. The device rotates with the motor shaft to generate a strong stirring force. The sediment in the sewage pool is stirred into suspended matter and inhaled. The pump discharges, improves the pump's anti-blocking and sewage discharge capacity, and completes the drainage, cleaning, desilting and saving operation costs at one time. It is an environmentally friendly product with obvious advancement and usability. Note: JYWQ and JBWQ are ordinary type automatic mixing and discharging sewage pumps; JPWQ is a stainless steel jacket internal circulation cooling system to automatically mix the sewage pump.

Main features of JYWQ automatic mixing sewage pump

1. When the sewage pump is automatically stirred, the bottom sediment of the tank is automatically stirred to completely prevent the dirt from accumulating, without manual cleaning;

2. Unique impeller design with the function of chopping and tearing fibrous materials and debris;

3. The external circulation cooling system is adopted to make the sewage pump run at a low water level, reduce the starting frequency of the motor, and prolong the life of the motor;

4. National standard atlas recommended products;

5. Shanghai high-tech achievements transformation products.

JYWQ automatic mixing of sewage pump model meaning

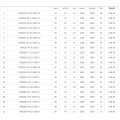

Example: 80JYWQ50-10-1600-3

80-row exit diameter (mm)

JYWQ-automatic mixing and sewage pump

50-flow (m3/h) 10-head (m) 1600-stirring range (mm) 3-motor power (KW)

JYWQ automatic mixing and discharging sewage pump main use

1. Discharge of heavily polluted wastewater from factories and businesses.

2. Drainage system of urban sewage treatment plants, hospitals and hotels.

3. Sewage drainage station in residential area.

5. Municipal engineering, construction sites.

6. Exploration, mining, and power plants are equipped with attached machines.

7. Rural biogas digesters, farmland irrigation, and river pond dredging.

JYWQ automatic mixing and draining pump use precautions

(1) Before operation, use a megger to check the Insulation resistance of the stator winding of the motor to ground, which is not less than 50 megohms.

(2) Check the cable for damage or breakage. If damage occurs, it must be replaced in time to avoid leakage; the cable cross section should match the current.

(3) The electric pump must not be started when the voltage exceeds ±10% of the rated voltage.

(4) In order to ensure the safety of use, the grounding wire in the four-core cable must be reliably grounded to prevent electric shock.

(5) When the electric pump is submerged into the water, it should be lifted vertically, and it is not allowed to land horizontally, and it should not fall into the sludge. When the battery is stopped, the electric pump should be lifted and cleaned, placed in a dry place, and protected from freezing.

(6) It is forbidden to use the cable as a hoisting rope.

(7) Check the rotor running direction and turn it clockwise from the top to the bottom.

(8) Outdoor switches or Terminals should be protected from rain and moisture. Do not touch the switch when wet or barefoot to prevent electric shock.

(9) When moving the electric pump, the power must be cut off. When the electric pump is running, people should not touch the water source to prevent personal accidents from leakage.

(10) It is strictly forbidden to run the phase of the motor. If the fuse is found to be blown, the cause should be checked before use. Do not arbitrarily thicken the fuse.

(11) When the pump is running, it should be managed by a special person. If abnormality is found, it should be stopped immediately to check and eliminate the fault. (refers to the case of the automatic protection cabinet at the end).

(12) After the electric pump has been operating normally under the specified working medium conditions for half a year, the oil chamber sealing condition should be checked. If the oil in the oil chamber is milky or has water precipitation, the mechanical oil and mechanical seal No. 10-20 should be replaced in time. For electric pumps used under severe working conditions, they should be inspected frequently.

(13) The user should select the appropriate flow head according to the actual working conditions to achieve good results. The parameters shown on the pump nameplate or the manual are the best working conditions. The user can choose (0.7~1.2) times better. Use within the flow, prohibit super-flow use, otherwise the flow is too large, the lift is too low and the motor is overloaded.

Product Categories : Sewage Wastewater Pump